Excavator manuals are crucial guides, offering detailed insights into operation, maintenance, and repair procedures for these powerful machines․ They ensure safe and efficient utilization, maximizing productivity and longevity․

What is an Excavator?

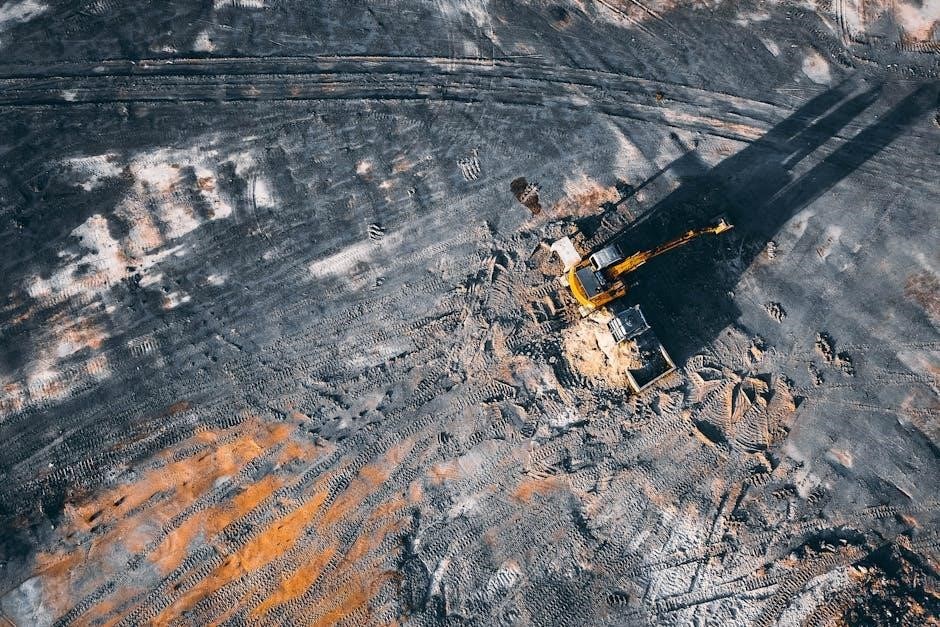

An excavator is a heavy construction machine, fundamentally designed for digging, but possessing remarkable versatility․ These machines excel at tasks like excavating, demolishing, material handling, and even dredging․ They consist of three primary sections: the undercarriage providing stability, the house containing the engine and operator’s cab, and the boom, arm, and bucket assembly responsible for digging and lifting․

Excavators come in a wide range of sizes, from compact models ideal for urban construction sites to massive machines employed in large-scale mining operations․ Their primary function revolves around digging pits, trenches, and foundations, but their adaptable nature allows for various applications․ Understanding the excavator’s core components is vital, and excavator manuals provide detailed diagrams and explanations of each part’s function;

The Importance of Excavator Manuals

Excavator manuals are indispensable resources for operators, maintenance personnel, and owners․ They provide critical safety precautions, detailed operating instructions, and comprehensive maintenance schedules, ensuring the machine functions reliably and safely․ Ignoring the guidance within these manuals can lead to costly repairs, reduced lifespan, and potentially dangerous situations․

A well-maintained excavator, guided by its manual, experiences minimized downtime and maximized productivity․ Manuals also contain vital troubleshooting sections, assisting in diagnosing and resolving common issues efficiently․ Furthermore, they often include detailed parts catalogs, simplifying component identification and replacement․ Accessing the correct excavator manual is the first step towards responsible ownership and operation, safeguarding both the machine and its operator․

Excavator Components and Their Functions

Excavator manuals detail the undercarriage, house, boom, arm, and bucket – essential components working in unison for digging, lifting, and overall operational efficiency․

Undercarriage: Tracks, Blades, and Stability

Excavator manuals dedicate significant sections to the undercarriage, emphasizing its role in stability and mobility․ They thoroughly explain track maintenance – tension adjustments, wear inspections, and replacement procedures – crucial for preventing costly downtime․ Manuals detail blade types (straight, universal, rock) and their optimal use for various terrains and tasks, including grading and leveling․

Detailed diagrams illustrate component locations and proper lubrication points․ Troubleshooting guides address common issues like track slippage or uneven wear․ Manuals also cover the importance of regular inspections for damaged rollers, idlers, and sprockets․ Understanding the undercarriage’s function, as outlined in the manual, is paramount for safe operation and maximizing the excavator’s lifespan, ensuring consistent performance across demanding job sites․

The House: Engine, Hydraulics, and Cab

Excavator manuals provide extensive coverage of the “house,” encompassing the engine, hydraulic systems, and operator’s cab․ Engine sections detail maintenance schedules – oil changes, filter replacements, and coolant checks – vital for optimal performance․ Hydraulic system diagrams illustrate fluid lines, pump locations, and valve functions, aiding in troubleshooting leaks or pressure issues․

Manuals emphasize safety procedures when working with high-pressure hydraulics․ Cab sections cover controls, instrumentation, and safety features like ROPS (Roll-Over Protective Structure) certification․ Detailed instructions guide users through cab filter replacements and routine inspections․ Understanding the house’s components, as detailed in the manual, is crucial for efficient operation, preventative maintenance, and ensuring a safe working environment for the operator․

Boom, Arm, and Bucket: Digging and Lifting Mechanisms

Excavator manuals dedicate significant sections to the boom, arm, and bucket – the core digging and lifting components․ These sections detail proper lubrication points for smooth operation and reduced wear, alongside inspection procedures for cracks or damage․ Manuals illustrate the mechanics of each component, explaining how they work in unison to achieve digging depth and lifting capacity․

Detailed diagrams showcase pin and bushing locations, crucial for maintenance and replacement․ Troubleshooting guides address common issues like reduced digging force or difficulty controlling the bucket․ Safety warnings emphasize load limits and proper lifting techniques․ Understanding these mechanisms, as outlined in the manual, ensures efficient excavation, safe operation, and prolongs the lifespan of these critical components․

Types of Excavators and Corresponding Manuals

Excavator manuals vary by machine size – small, medium, large, and demolition models – each offering specific operational guidance and maintenance schedules tailored to its capabilities․

Small Excavators (0-8 Tonnes) ⸺ Manual Focus

Manuals for small excavators, ranging from 0 to 8 tonnes, prioritize ease of use and comprehensive coverage for operators with varying experience levels․ These guides typically emphasize compact design advantages, versatility in urban environments, and straightforward maintenance procedures․ Expect detailed sections on daily checks, fluid level monitoring, and basic troubleshooting steps․

A key focus is on safe operation within confined spaces, highlighting stability considerations and proper digging techniques․ The manuals often include illustrations and diagrams to clarify complex procedures, alongside clear explanations of control functions․ Component-specific instructions, particularly for the undercarriage and hydraulic systems, are also prominent․ Furthermore, these manuals frequently detail transport and storage guidelines, ensuring the longevity and optimal performance of these agile machines․

Medium Excavators ー Manual Specifics

Manuals for medium excavators delve into more complex systems compared to their smaller counterparts, reflecting increased capabilities and operational demands․ These guides provide in-depth coverage of hydraulic systems, engine diagnostics, and advanced control features․ Expect detailed schematics and troubleshooting flowcharts to assist with repairs and maintenance․

A significant portion focuses on optimizing digging performance, including bucket selection, digging techniques for various soil types, and efficient operation strategies․ Safety protocols are extensively detailed, covering load limits, stability considerations, and emergency procedures․ Manuals also emphasize preventative maintenance schedules, outlining regular inspections and component replacements to minimize downtime․ Furthermore, they often include sections on attachment operation and maintenance, reflecting the versatility of these machines․

Large Excavators (50-800 Tonnes) ー Detailed Manuals

Manuals for large excavators are exceptionally comprehensive, reflecting the immense scale and complexity of these machines․ They feature exhaustive sections on engine systems, often including detailed fuel injection and emission control information․ Hydraulic systems are covered with extensive schematics, addressing high-pressure components and advanced control valves․

Safety is paramount, with detailed procedures for rigging, lifting, and operating in hazardous environments․ Troubleshooting guides are extensive, covering a wide range of potential issues․ These manuals also include detailed maintenance schedules, emphasizing critical component inspections and replacements․ Expect in-depth coverage of undercarriage maintenance, given the significant loads these machines bear․ Furthermore, specialized sections address operation in demanding job sites, ensuring 24/7 reliability․

Demolition Excavators ⸺ Specialized Manual Content

Manuals for demolition excavators contain unique content focused on specialized attachments and safety protocols․ Expect detailed instructions for operating shears, breakers, and grapples, including load limits and proper mounting procedures․ Enhanced safety sections cover guarding requirements, fall protection, and procedures for working on unstable structures․

These manuals emphasize stability considerations during demolition, detailing outrigger setup and ground assessment techniques․ Troubleshooting focuses on issues specific to high-impact work, such as hydraulic line failures and structural component stress․ Maintenance schedules prioritize inspection of reinforced structures and attachment mounting points․ Detailed diagrams illustrate proper attachment operation and maintenance, ensuring operator safety and maximizing demolition efficiency․ Expect guidance on working near existing structures and minimizing collateral damage․

Understanding Excavator Manual Sections

Excavator manuals are logically structured, typically including safety guidelines, operational instructions, maintenance schedules, and detailed troubleshooting sections for efficient problem-solving․

Safety Precautions and Operating Instructions

Excavator manuals dedicate significant sections to safety, emphasizing pre-operational checks – inspecting fluid levels, hoses, and structural integrity – to prevent accidents․ Detailed operating instructions cover starting, stopping, maneuvering, and utilizing attachments, stressing adherence to manufacturer guidelines․

Manuals clearly outline rollover prevention techniques, proper load handling procedures, and the importance of wearing appropriate personal protective equipment (PPE)․ They also detail emergency shutdown procedures and safe evacuation protocols․ Understanding the machine’s capabilities and limitations, as described in the manual, is paramount․ Operators must familiarize themselves with all warning labels and indicators․

Furthermore, manuals often include specific instructions regarding working near underground utilities and maintaining a safe distance from power lines, reinforcing a commitment to operator and bystander safety․

Maintenance Schedules and Procedures

Excavator manuals provide meticulously crafted maintenance schedules, categorized by operating hours or calendar intervals, ensuring optimal performance and longevity․ These schedules detail routine tasks like fluid checks (engine oil, hydraulic fluid, coolant), filter replacements (air, fuel, hydraulic), and lubrication of critical components․

Procedures for inspecting and maintaining the undercarriage – tracks, rollers, and idlers – are thoroughly explained, alongside guidance on hydraulic system maintenance, including hose inspections and cylinder seal checks․ Manuals also cover engine maintenance, detailing valve adjustments and injector cleaning․

Detailed step-by-step instructions, often accompanied by diagrams, guide technicians through each procedure, specifying required tools and torque specifications․ Adhering to these schedules minimizes downtime and prevents costly repairs․

Troubleshooting Common Issues

Excavator manuals dedicate significant sections to troubleshooting, assisting operators and technicians in diagnosing and resolving frequent problems․ These sections typically employ a symptom-based approach, guiding users through a series of diagnostic questions to pinpoint the root cause of issues like engine failure, hydraulic system malfunctions, or electrical problems․

Detailed flowcharts and diagnostic tables help identify potential causes, ranging from simple fixes like clogged filters to more complex issues requiring component replacement․ Manuals outline specific tests to perform, utilizing diagnostic tools to verify findings․

Clear instructions are provided for implementing corrective actions, including component repair or replacement procedures․ Safety warnings are prominently displayed, emphasizing precautions to prevent injury during troubleshooting and repair․

Accessing Excavator Manuals

Excavator manuals are readily available through online databases, manufacturer websites like Hitachi, Volvo, and Caterpillar, and integrated spare parts catalogues for convenient access․

Online Manual Databases and Resources

Numerous online platforms specialize in providing excavator manuals and related documentation․ These databases often compile manuals from various manufacturers, offering a centralized location for locating specific models․ Subscriptions may be required for full access, but the convenience and breadth of resources can be invaluable․

Several websites aggregate technical documentation, including operator’s manuals, maintenance guides, and parts catalogs․ These resources frequently allow searching by manufacturer, model number, or serial number, streamlining the process of finding the correct manual․

Furthermore, online forums and communities dedicated to heavy equipment often feature shared manual links and discussions about accessing documentation․ While verifying the authenticity of downloaded manuals is crucial, these platforms can provide valuable leads and support․ Always prioritize official manufacturer sources when possible to ensure accuracy and completeness․

Manufacturer Websites (Hitachi, Volvo, Liebherr, Hyundai, Caterpillar)

Directly accessing excavator manuals from the manufacturer’s website is often the most reliable method․ Companies like Hitachi, Volvo, Liebherr, Hyundai, and Caterpillar typically offer dedicated sections for support and documentation․ Registration may be necessary, sometimes linked to machine serial numbers, to verify ownership and unlock access․

These websites frequently provide downloadable PDF manuals, interactive online versions, and supplementary resources like parts catalogs․ Caterpillar, for example, offers extensive documentation on Cat․com for their various excavator models․ Hyundai provides comprehensive service manuals for their excavators as well․

Manufacturer websites ensure the manuals are up-to-date and specific to your machine’s configuration, minimizing the risk of using incorrect information․ They also often include safety updates and revisions, crucial for safe operation and maintenance․

Spare Parts Catalogues and Manual Integration

Excavator manuals are significantly enhanced when integrated with spare parts catalogues․ These catalogues, often available through manufacturers or specialized suppliers, provide detailed diagrams and part numbers, crucial for accurate repairs․ Many modern manuals now include QR codes or direct links to relevant parts information, streamlining the identification process․

Accessing both resources simultaneously allows technicians to quickly locate the correct components while referencing the manual’s repair procedures․ This integration minimizes downtime and reduces the risk of ordering incorrect parts․ Some online platforms offer a combined search function, allowing users to search for parts directly within the manual’s context․

Effective use of spare parts catalogues alongside excavator manuals is essential for efficient maintenance and repair, ensuring optimal machine performance and longevity․

Using Excavator Manuals for Effective Maintenance

Excavator manuals guide preventative maintenance schedules and detailed repair procedures, ensuring optimal performance and extending the lifespan of these complex machines․

Preventative Maintenance Based on Manual Guidelines

Excavator manuals are paramount for establishing a robust preventative maintenance program․ These guides detail specific inspection intervals, fluid level checks (engine oil, hydraulic fluid, coolant), and filter replacement schedules – crucial for avoiding costly downtime․ Following these guidelines minimizes wear and tear on critical components like the undercarriage, engine, and hydraulic systems․

Manuals also outline lubrication points, ensuring smooth operation and reducing friction․ Regular greasing of pins and bushings extends their lifespan significantly․ Furthermore, they specify torque specifications for bolts and fasteners, preventing loosening due to vibration․ Adhering to the manufacturer’s recommendations, as detailed in the manual, guarantees optimal performance, enhances safety, and ultimately protects your investment in the excavator․

Repair Procedures and Component Replacement

Excavator manuals provide step-by-step repair procedures, essential for addressing mechanical issues effectively․ They detail disassembly and assembly instructions, torque specifications, and wiring diagrams, enabling technicians to diagnose and resolve problems accurately․ Component replacement sections offer detailed guidance, including part numbers and exploded views, simplifying the process of sourcing and installing new parts․

Manuals emphasize safety precautions during repairs, highlighting potential hazards and necessary protective measures․ They also specify the correct tools and equipment required for each task, preventing damage to the excavator․ Following these procedures ensures repairs are completed correctly, maintaining the machine’s integrity and preventing further complications․ Proper manual adherence is vital for skilled repairs and prolonged excavator life․